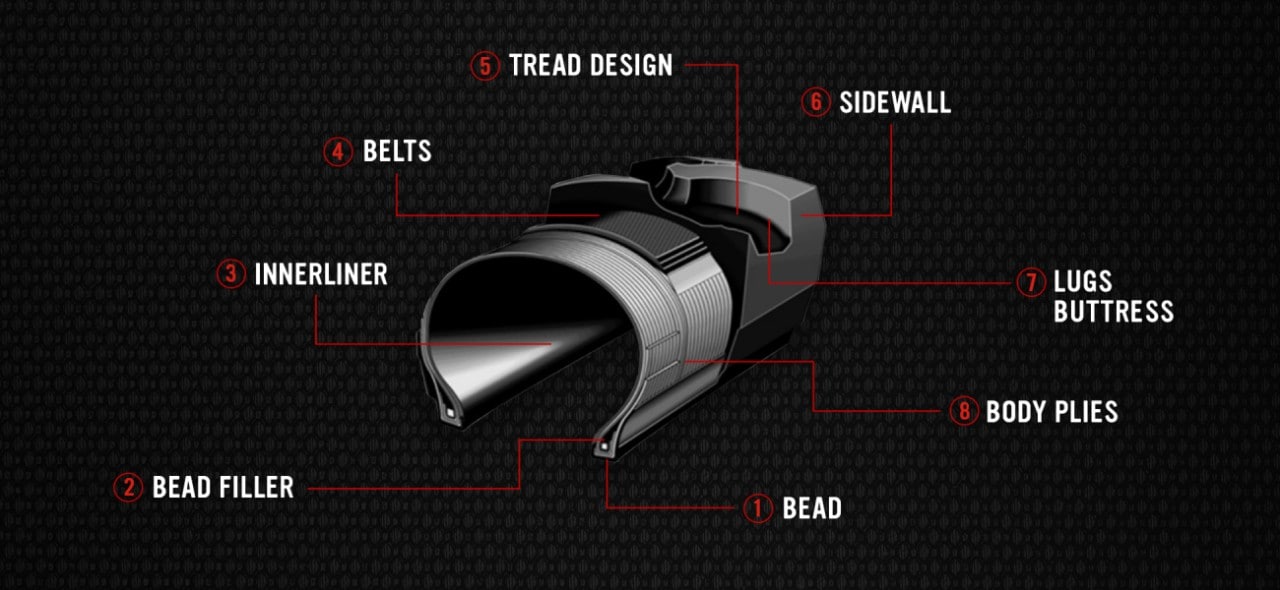

1. Bead

Beads Anchor the tire to the rim and allow the tire to stay "seated" on the wheel.

It's important to familiarize yourself with the basic anatomy of agricultural tires including each of the tire’s components to understand how tire construction impacts tire performance. Using this information, you can have a better understanding of the role each tire component plays in ensuring your farm’s tires are achieving top performance when you head into the field for soil prep, planting, spraying and harvest.

Beads Anchor the tire to the rim and allow the tire to stay "seated" on the wheel.

Bead Fillers stabilize the lower sidewall by enveloping the bead and extending up tin the sidewall to maximize stability, steering response, and case durability.

Liners protect the cord body by insulating the tubes from the cords. Liners are essential for resisting air and moisture permeation.

Belts determin the shape, or footprint, of the tire. Belts work in conjunctio with the cords to add stability and stregnth.

Treads serve to interact with the soil or paved surface and provide traction. Tread design varies between tires to maximize traction and resist wear and tear.

Sidewalls are made of flexible rubber and provide lateral stability. The sidewalls keep the body plies and innerliner of the tire protected from stubble and debris. Sidwall flex is a big factor in deciding what tire is right for what job and what peice of equipiment.

Lug depth is important for traction. together with the lug buttress, this component provides tread stability.

Cords run radially from bead to bead and determine the strength of the tire, determine its load capacity and provide lateral stability.

Armed with this information, the next decisions you will need to make is whether to purchase radial or bias tires, and what size should your tractor tires be?

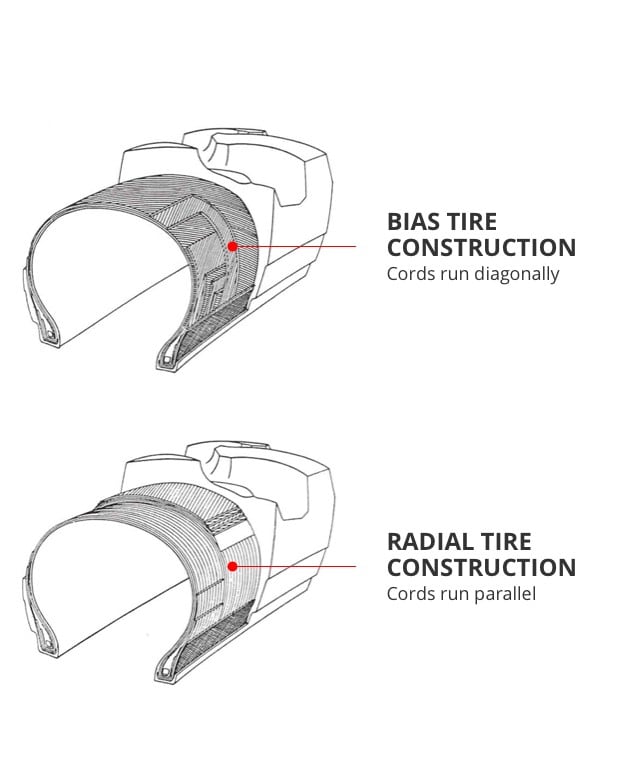

Bias ply tires engineered with multiple plies of rubber criss-crossed over one another. Thus, the sidewall and tread are connected. Conversely, radial tires are made of two separate parts. The body plies run perpendicular to the bead and the undertread hugs the tires circumference with steel belts. This way, sidewall movement isn't transferred into the tread so radials offer reduced soil compaction. To sum up the debate, bias tires are great for forestry, or non-tillage equipment and they cost less than radials. Radials have a larger footprint for better traction and reduced soil compaction. Plus they're more fuel efficient. A certified Firestone Ag Dealer can help to determine the correct type of tire for your needs.

Cost-sensitive solutions

Bias tires are perfect for smaller, lightweight production equipment that requires extra stability for non-tillage work.

Dependable fuel economy

Increased traction helps with fuel economy and allows you to cover more ground. Radial tires can last up to 30% longer than bias tires. Radial tires with AD2 technology allow you to carry more load at lower inflation pressure.

AD2 tires have a larger footprint that can help improve the productivity of today's heavier equipment with less time in the field and reduced fuel consumption.

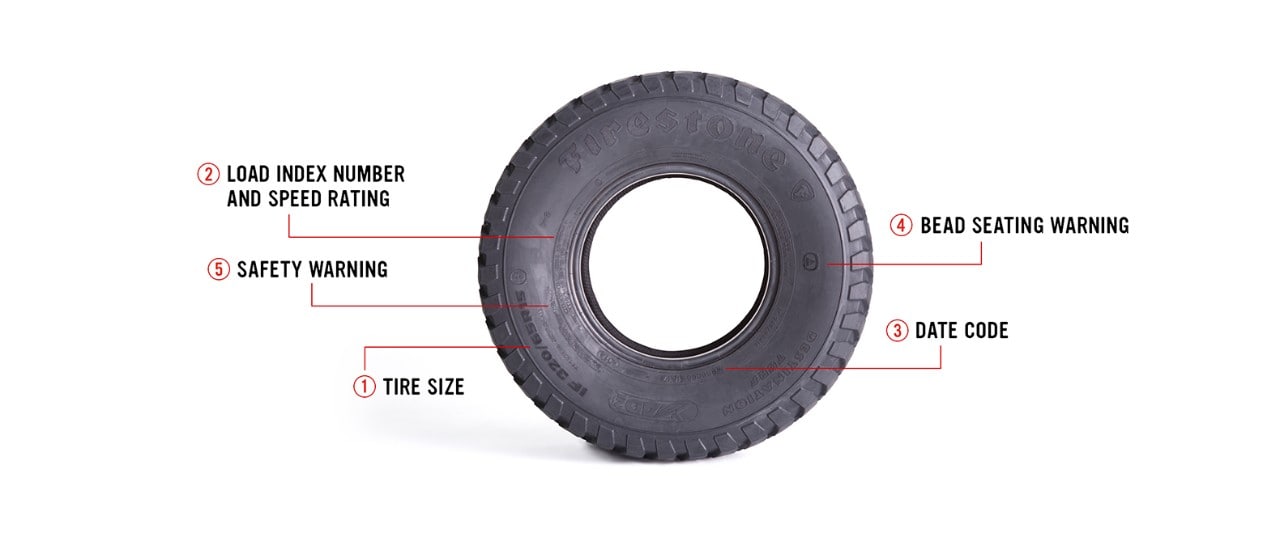

When choosing the right tire size for your tractor and your farm’s traction needs, you will be looking at a set of numbers on the sidewall of your tire for guidance.

For additional help understanding each of these measurements and choosing your tires you can read our How to Read a Tire Guide

Firestone tractor tires with AD2 technology are specifically engineered for today's high-horsepower equipment.

Destination Farm radial implements can outperform equivalent sized bias and radial-ply truck tires commonly used to carry heavy implements.

Firestone sprayer tires with AD2 technology may help solve many of the load and compaction problems of today's larger equipment.

Cyclical Field Operation (CFO) harvest tires are specifically built for the exceptional demands of combines and grain carts.

Regular Agriculture

Premium Tread Agriculture

Wet Farming Applications

Shallow Industrial

Construction and Light Industrial